Thank you for Checking out SmokerBuilder.com! On this page I will be posting a series of articles teaching you How to Build a Reverse Flow Smoker.

Thank you for Checking out SmokerBuilder.com! On this page I will be posting a series of articles teaching you How to Build a Reverse Flow Smoker.

Part-1 What is a Reverse Flow Smoker?

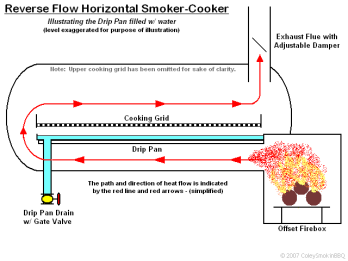

A Reverse Flow Smoker is a smoker which utilizes a “Baffle Plate” that is welded in solid in the “Cook Chamber” to control the flow of smoke and heat.

First lets cover some basic definitions:

- Baffle Plate– a plate of solid steel usually one quarter of an inch or greater in thickness which not only controls the flow of smoke and heat through the cook chamber but also absorbs heat and radiates the heat for more even cooking chamber temps.

- Cook Chamber- this is the space where the meat is actually cooked. The Cook Chamber is after the fire box in the order of flow of the products of combustion.

- Fire Box– the space where the fire is actually built. Can be square or round in shape depending on the style of the build. It has controlled air inlets and must be sized appropriately based on the dimensions of the cook chamber.

- Products of Combustion– heat, smoke, gases, and other particles produced by the combustion of the wood or other fuel consumed in the fire box.

- Stack– the exhaust stack leaving the cook chamber often referred to as the smoke stack. It must be sized appropriately based on the dimensions of the firebox and the cook chamber dimensions

Design Considerations.

When designing your smoker you should consider how big you want it to be and how transportable it needs to be. Reverse Flow Smokers can become very heavy as you build them. It is important to consider the uses you want the smoker for.

A few questions to consider are:

- How big are the crowds I will be serving most of the time?

- What materials do I have the best access to?

- What kind of materials am I set up to work with the best?

- Will I need to transport this smoker often?

- What will I be cooking on this smoker?

- How am I going to get this thing home?

Knowing the answers to these questions will make your build more enjoyable and less troublesome. One of the builds I will be featuring on this site is a trailer smoker build. I have a lot of friends who request me to cook for various functions. Having a trailer smoker is very handy for these occasions. During this build I used a forklift for moving and lifting the smoker.

The Cook Chamber.

The Cook Chamber is where the meat or other food is cooked. The cook chamber can have a single grill in it or multiple shelves. It can have a single door or several doors. It can be made of several kinds of materials such as mild steel or stainless steel. It can be square or round. Some Builds use tanks, pipe, flat steel, or rolled steel. I have used old water tanks from concrete trucks, air tanks and I’ve had flat sheets of steel rolled up to make my cook chambers. Other things that can be used are Propane Tanks, fuel tanks, old air compressor tanks, billboard sign posts, or even expansion tanks. A great source for these items is the local scrap yard. A walk through the scrap yard is like a treasure hunt, Ive found some great materials and even found all the materials I needed for some of my builds! Knowing how you plan to use the smoker before you start your build can save you a lot of work. This will help you know how big and what size cook chamber to look for.

Part-2 will begin with the Fire Box. Thanks for reading!

Click Here to get Expert Advise!

Reverse Flow Smoker Part-2

A Fire Box is needed on a Reverse Flow Smoker for the purpose of having an inderect heat source for slow cooking and smoking meat and other food. The Fire Box is built using 1/4 inch plate for thickness and durability. It must be sized properly to promote complete combustion and also to allow for enough BTU’s for cooking properly. The fire box is sized approximately 30% the size of the cook chamber. When smoking meat this is very important for food safety. For meat and poultry to remain in the safe zone while smoking, the temperature of the meat needs to move from below 40*F to above 140*F as quickly as possible. Less than 4 hours is the magic number.

Click here to see this featured build in progress!

Complete combustion is very important. One sign of complete combustion is the smoke leaving the smoke stack will be thin and blue in color. Thick, white, belowing smoke is an indicator of incomplete combustion. It will leave a sooty, bitter, too smokey taste on the meat. Proper sizing of the parts of the smoker is the most important way to prevent incomplete combustion.

The Fire Box includes an air inlet control that allows for control of the amount of air (called combustion air) for the purpose of controling the fire. This air inlet control, or Damper, is opened or closed to limit the amount of combustion air entering the fire box causing the fire to be smaller or larger which in turn affects the temperature of the cook chamber.

A Reverse Flow Smoker utilizes a Baffle Plate which runs across the bottom of the cook chamber with a gap at the end of the plate farthest away from the fire box. This Baffle Plate is welded in solid except for the Gap end of the plate. The Baffle Plate catches drippings from the meat and can even be partially filled with water or fruit juices which can be used to flavor the meat and provide some humidity in the cook chamber.

The Baffle Plate serves two purposes, first to act as a heat sink to absorb heat and allow for radiant heat to cook the meat and second to restrict the Draft in the smoker to assist with complete combustion. The Fire Box is attached to the cook chamber as in the drawing attached and a mating hole is cut between them. This hole must be sized properly. If the hole is too big the smoker will have too much draft causing uneven cooking temps, not big enough and the smoker will run cold. I will cover the ratio’s in another segment. The Baffle Plate is installed about an inch above the top of the mating hole and sloping away from the fire box with a slight pitch. At the end of the Baffle Plate there is a drain which is welded into the bottom of the plate. this drain uses a standard Full Port Ball Valve for holding the water and drippings in during cooking and draining them when either done or if the plate gets too full.

Part-3 will start with the Baffle Plate Gap. Thanks for reading!!!

Click Here to get Expert Advise!

How to Build a Reverse Flow Smoker Part-3

Hello again and welcome to part-3 of our series on How to Build a Reverse Flow Smoker.

I would like to first of all invite you to be a member of our site. If you still are not a member please sign up! We would like to have you join our community. It’s free to join our community and take advantage of all the information that’s available to you. Becoming a member allows you to post and ask questions in our forums.

Now on to more about How to Build a Reverse Flow Smoker. Today we will be discussing the Baffle Plate and the Baffle plate Gap.

The Baffle Plate is what puts the “reverse flow” into the reverse flow smoker. If you reference the above drawing from part-2 you will notice there is a plate running from the fire box across the cook chamber and stopping short of the opposite end of the cook chamber. This is the Baffle Plate. The purpose of this plate is to direct the flow of the products of combustion to the opposite end of the cook chamber and in the process to absorb heat from them. Since the plate is absorbing the heat from the products of combustion, it radiates upward to cook the food that is being smoked. This allows for what is referred to as the “the indirect heat method” of cooking. the plate will radiate heat for more evenly reducing hot spots in the cook chamber. At the end of the Baffle Plate is a gap. This gap must be sized properly for the plate to work correctly, which brings us to talking about some fluid dynamics kind of stuff. You ready for this? LOL.

OK here it goes (I’m going to try to make this simple). Since air has mass it is a fluid, not a liquid, a fluid. Air can be blown, or pumped, and moves from one space to another. So lets think about this using water for example. If you have a bucket sitting on the floor which appears to be empty and you want to fill it with water, what must happen? Well in order for the water to occupy the space inside the bucket, first the air must come out. The only way the air and the water could occupy the space in the bucket would be to seal the container and force them both into the same space, thus increasing the pressure inside the bucket. OK so the air in the bucket would be compressed, since a liquid can not be compressed, and this would increase the pressure in the sealed bucket.

Now you are asking “what does this have to do with a smoker?” Lets talk about air pressure then.

The air we breath is filling the space around us and since it is at equilibrium, we call it 0 psi, or atmospheric pressure. If we have a container with pressurized air in it and we open it, all the air that is in the container will escape until the space in the container and the space outside the container is equalized in pressure. Still with me? We are going to start applying this to the smoker now.

In the bottom of the Reverse Flow Smoker we are building, we want the products of combustion to move from the fire box to the cook chamber and then out of the cook chamber and out the stack. If we want the plate to absorb the heat evenly we need to control the way that the air, containing the products of combustion, is moving under it. The gap at the end of the plate is one of the ways we control that air movement. The gap is sized to allow the correct amount of air move through it and then on to the cook chamber. We need to talk a little about some aerodynamics. Since air has mass it moves similar to water. Lets think about a creek for a moment. Think about the path the water in the creek takes when it encounters an obstruction. It will move around the obstruction and on the opposite side of the obstruction the water will form an eddie and swirl around a little bit. Air will act the same way when it encounters an obstruction in it’s path. Another thing that effects the way air moves is called Skin Friction. Skin Friction is the resistance across a surface whether we are talking about the bottom of our baffle plate or the inside surface of the tank or anything inside the tank that was installed or left in there. All of these things will cause the air to either come in contact or avoid the surface under the baffle plate. Any part of the surface area under the plate that does not have air moving over it will become a cold spot on the plate. It is very hard to avoid this. We just want to smoke meat, right? So we just deal with that.

Well if we do some Good Ol’ Boy Engineering, we can compensate for some of these things. For instance, I have found a way to make my baffle plates adjustable. We can also install some steel rod or some steel pipe on the inside of the tank along the bottom of the tank running the same direction as the air is moving and we can straighten out the air patterns and push some of the air up against the bottom of the plate.

If we design the baffle plate properly we will also be able to achieve proper combustion. Improper combustion will cause a heavy white smoke which will leave a bitter taste on the food that we are smoking. In the next post we will be talking more about the cook chamber and the smoke stack.

Thanks for reading!